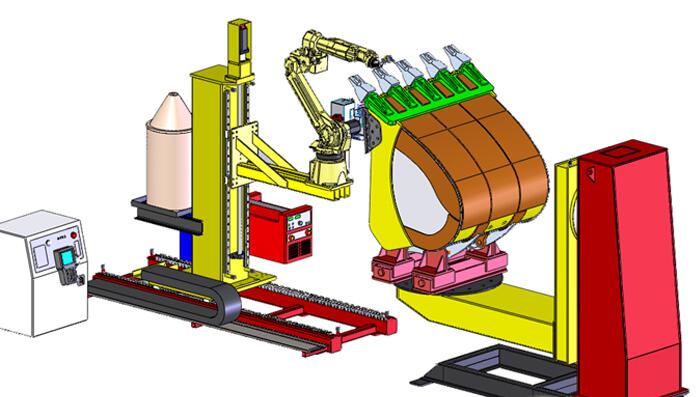

Excavator bucket welding robotic assembly solutions

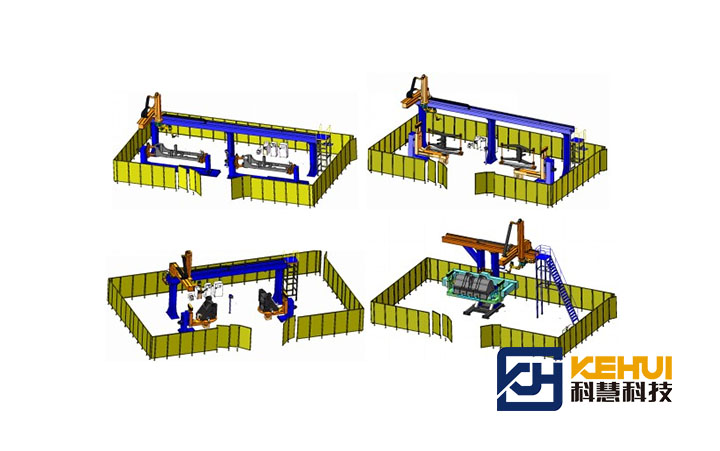

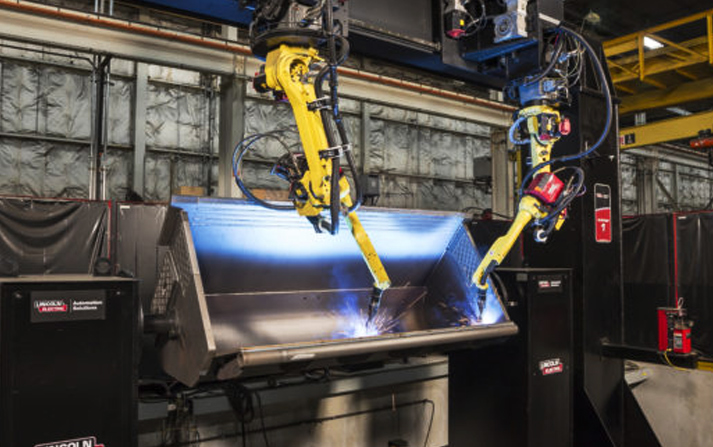

This excavator bucket welding robotic assembly solutions is specially developed to cope with the welding difficulties of construction machinery, and can achieve efficient and intelligent production. The robotic welding arm has high flexibility and can accurately complete the welding of various parts of the bucket, including complex parts such as edge reinforcement plates and bottom plate reinforcement ribs. This robotic assembly solutions is equipped with an automatic monitoring system to adjust welding parameters in real time to ensure that the strength and appearance of the weld meet industry standards.

Application:

Excavator bucket welding robotic assembly solutions are widely used in the automated welding tasks of structural parts and key components in many industries such as excavator accessories, loader buckets, bulldozer blades, crane booms, tractor shovels, crusher frames, mining conveying equipment, mixer trucks, container spreaders, etc.